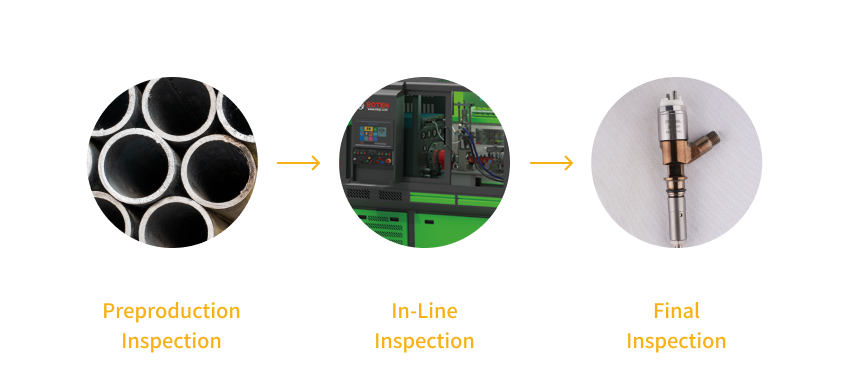

Quality Inspection

During the produce of 320D injector and spare parts, there are total 15 steps of quality inspection. They are the selection of raw materials, the inspection during production, and the inspection of finished products. In these 15 steps, one step missed can cause bad quality or failure production, therefore, every process has specific workers to be responsible, and that finally made our professional production team.

Here are some descriptions of 320D injector and spare parts’ produce processes:

1. Inspect raw materials and make a backup of the raw materials test report;

2. Cutting raw materials with blanking machine;

3. Inspect raw material’s cutting diameter and length;

4. Forging and forming processing on the raw materials;

5. Inspectors conduct the all kinds of inspections of forming blank;

6. Remove the blank scrap ;

7. Blast the surface of the blank;

8. Conduct surface treatment inspection after sandblasting;

9. Perform blank machining;

10. Process 320D injector and spare part’s body seal threading;

11. Process 320D injector and spare part body connection threading;

12. Process 320D injector and spare part’s hole;

13. The inspector conducts general inspection;

14. Install the 320D injector and spare part;

15. The packing workshop finishes product packaging.

Before sending out of the factory, the finished 320D injector and spare parts still need to undergo three inspections—full inspection, random inspection, and batch inspection. In these inspections, different brands of test benches are used to test the same 320D injector and spare part for a total of no less than three times.

Apart from the above, the 320D injector and spare part is one of the most important running parts, it is also one of the parts with the highest damage rate, even tiny particles can cause the failure of the 320D injector and part and even entire components. So it is important to make sure the whole production process and installation and its working place are dust-free.