1. 2645A751 Fuel Injector Quality Control

(1) Fuel Injector Testing

All fuel injectors are tested for electrical characteristics, accuracy, high temperature, low temperature, withstand voltage, leakage, durability, and various working conditions.

(2) Fuel Injector Assembling

For quality control during the production and installation process of injectors, our company strictly follows the standard product installation data and product installation steps for installation and testing, such as injector stroke test, injector solenoid valve tightening torque test, injector nozzle tightening torque test, etc.

(3) Fuel Injector Inspection

The factory inspection of the fuel injector is undergone full inspection, random inspection, and batch inspection three inspections. Different brands of test benches are used to test the same fuel injector for a total of more than three times for factory inspection, and the fuel injector installation testing environment are progressed in dust-free workshop.

2. 2645A751 Fuel Injector Technical Support

2.1. 2645A751 Fuel Injector Application Scenarios

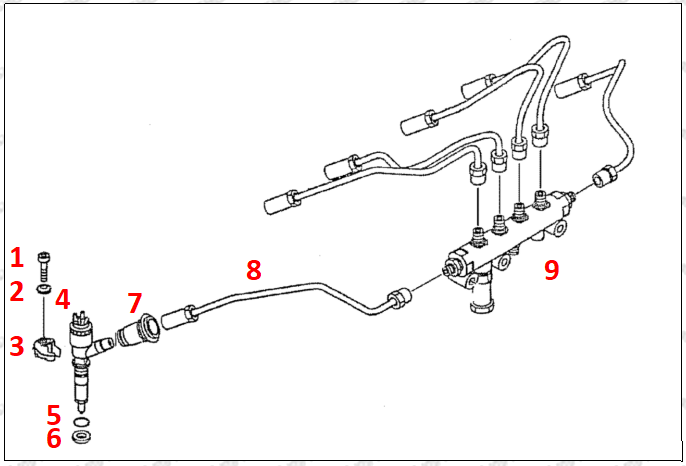

Pic No. 1

Matching Car Model: 320D excavator

| No. | Name | No. | Name | No. | Name |

| 1 | Adaptor Fixing Bolt | 2 | Gasket | 3 | Fuel Injection Adaptor |

| 4 | Fuel Injector | 5 | Fuel Injector O-Ring | 6 | Fuel Injector Nozzle Gasket |

| 7 | Intake Gasket | 8 | Intake | 9 | High Pressure Common Rail Pipe |

2.2. 2645A751 Fuel Injector Installation Precautions

The replacement of the fuel injector must strictly follow the electrical system, the approved pressure of the low-pressure fuel intake system, the approved pressure of the high-pressure fuel circuit system, and fuel system replacement consumables requirements (including the low-pressure fuel circuit system filter and the high-pressure fuel circuit) specified in the vehicle engine maintenance manual;

Replacement of wearing parts of the fuel system, cleaning requirements for the connection between the fuel system and the fuel injector, the fitting clearance of the fuel injectorconnection, the installation angle and tightening torque of the fuel injector, the fitting clearance of the intake system, and the fitting clearance of the exhaust systemto ensure the service life of the engine and the normal operation of the fuel

When installing the fuel injectoron the engine, it is necessary to clean the engine block, cylinder head and other parts connected to the fuel injector,and ensure that there is no dust, carbon deposits, water, rust spots, etc.

Before installing, check whether the fuel injectornozzle gasket has been replaced and installed on the fuel

When installing the fuel injector, apply lubricant between the fuel injector, fuel nozzle sealing gasket and O-ring.

Failure to replace the gasket with a new one may lead to: deformation of the tight cap of nozzle, deformation of nozzle, deformation of nozzle orifice, oil leakage and air leakage, which will cause serious damage to the fuel injector andnozzle to break and cause damage to the engine.

3. Copyright Statement

The content, graphics, images, design and other materials in this passage are protected by copyright law and are the property of www.320dinjector.com. Permission is granted to visitors for the sole purpose of personal, non-commercial use, and you must retain all copyright and other proprietary notices contained in the original materials. Any other use of the materials including reproduction, modification, distribution, or republication without the prior written permission of www.320dinjector.com is strictly prohibited.

For permission requests or further information, please contact us via hison@shumatt.com.